| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

TELCİMAKS MAKİNA İMALAT İTH. İHR. SAN. TİC. LTD. ŞTİ.

Fevzi Çakmak Mah. 10753 Sok. No: 5/A / Karatay / KONYA / TÜRKİYE

|

Contact Info: +90 544 342 0255

|

Hall: 7

Stand: 716A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

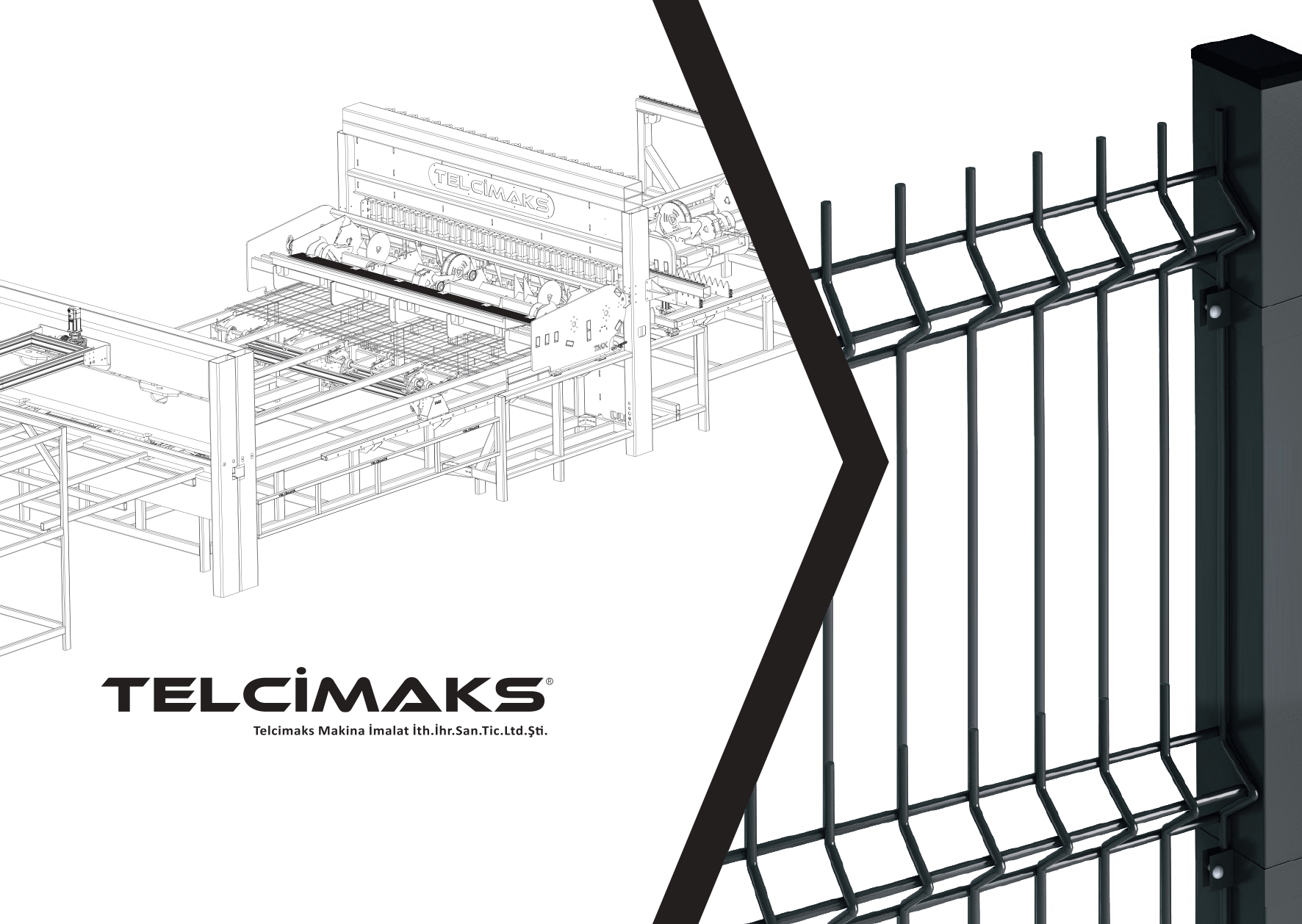

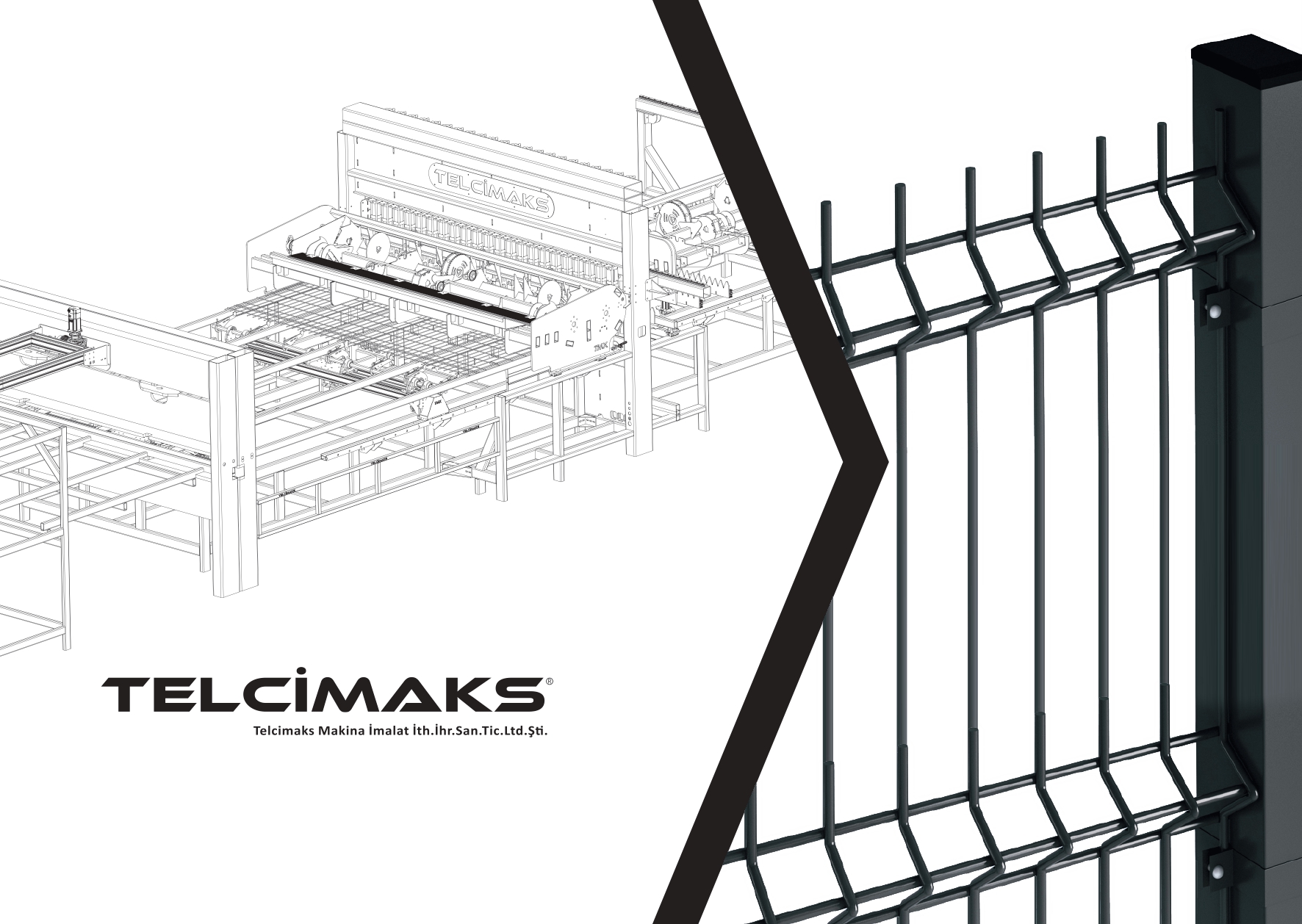

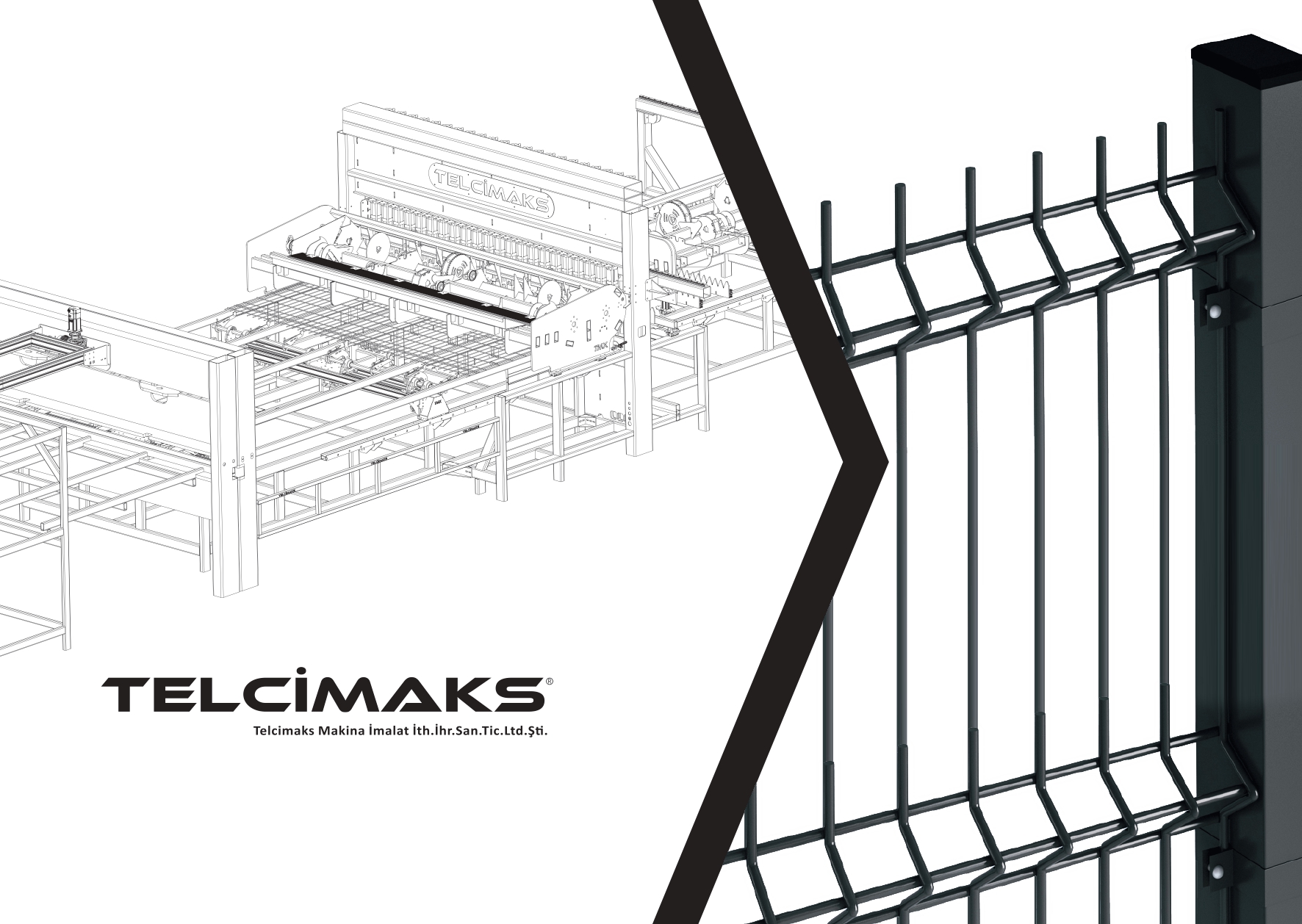

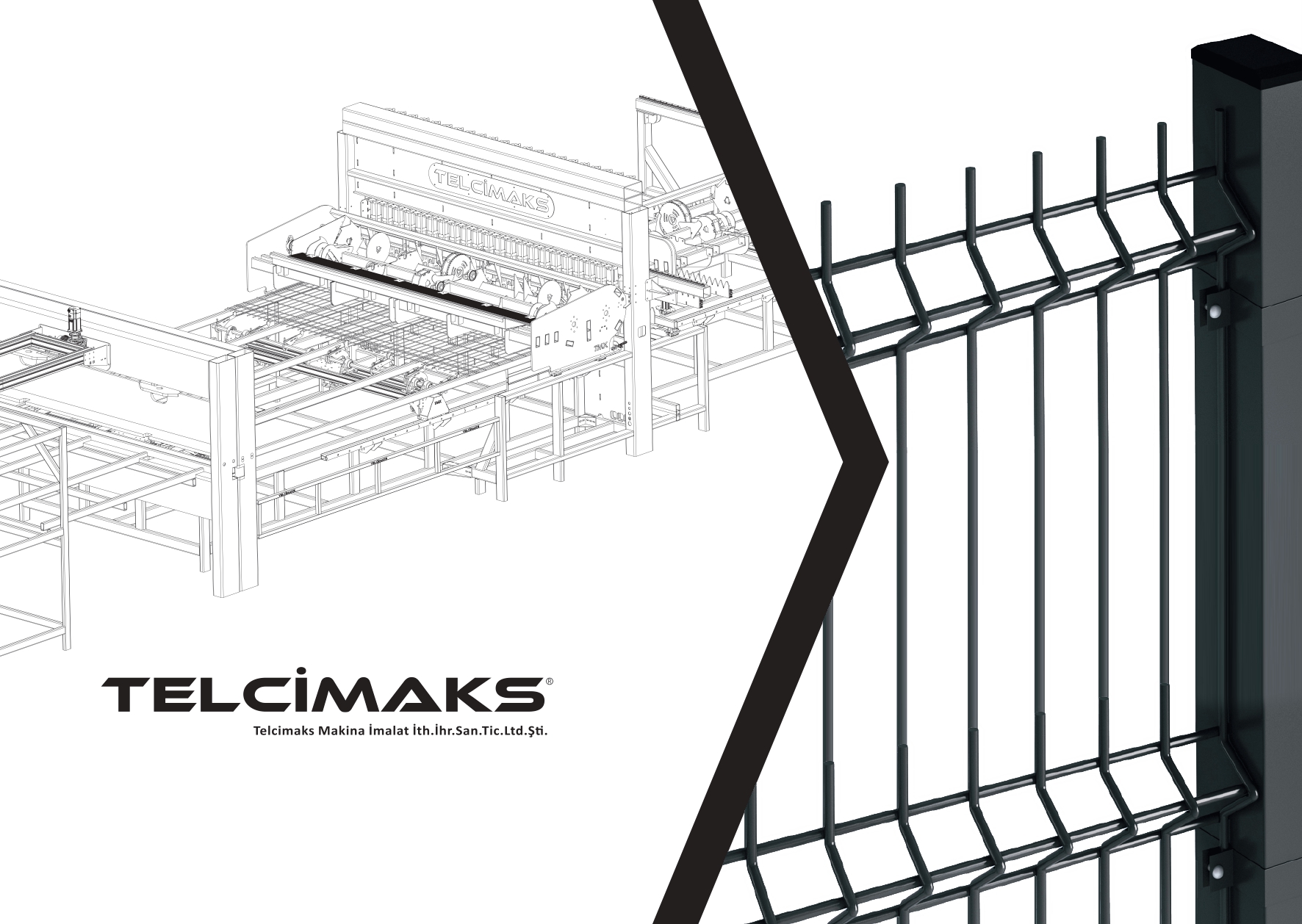

TELCİMAKS MAKİNA manufactures is a company that produces 7 different machines for wire processing. There are more than 500 machines working in 40 countries and these numbers are increasing day by day. We work with more than 30 personnel in our own factory with a indoor area of 6.000 square meters. We aim to develop our product range to cover all wire processing and auxiliary mechanisms and equipment. World is changing. Instead of high-quality, incredibly expensive machines, there are quality, intelligently designed and customized but cheap machines.Developed countries are forced to stop producing low / medium technology machines. Instead, it is necessary to produce smartly designed, practical, useful, affordable machines that contain the necessary technology and engineering, in our opinion. If you interested in one of our products; Or if you need any special need, Our sales and after sales team, who can speak several languages at a good level, is ready to contact you.

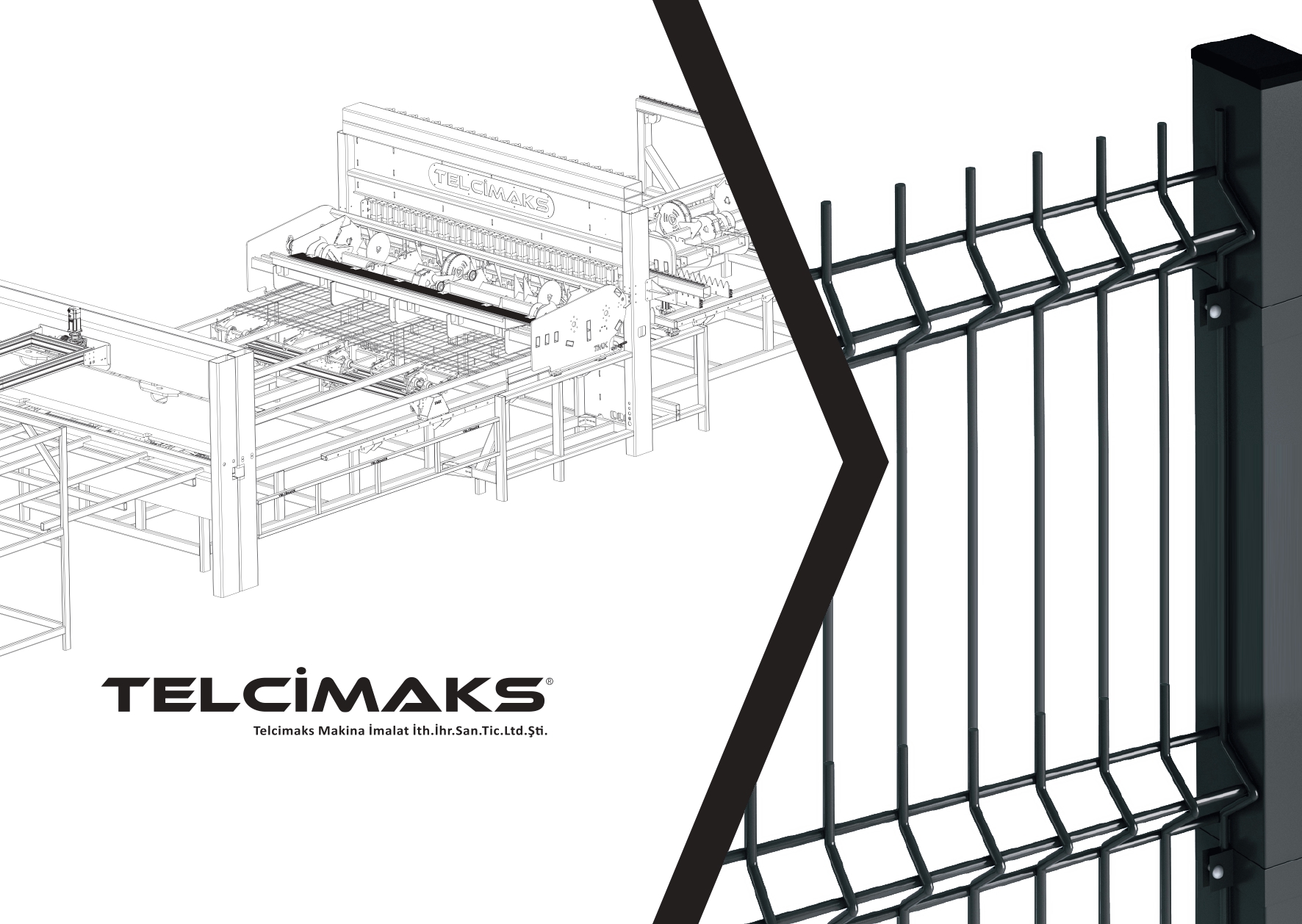

Panel Mesh welding machines, can made standard welded panel production in desired dimensions to be used, environmental and security system, industrial areas, military facilities. According to specifications and capacity, 90 kVA - 120 kVA - 150 kVA high technology transformer, can used in panel mesh welding machines. It welds straightened and cut wires in desired wire thicknesses to each other. According to the customer s request, transformer power and quantity, automatic length wire mechanism, twisting press and stacking robot can be added to panel welding machines.

Panel Mesh welding machines, can made standard welded panel production in desired dimensions to be used, environmental and security system, industrial areas, military facilities. According to specifications and capacity, 90 kVA - 120 kVA - 150 kVA high technology transformer, can used in panel mesh welding machines. It welds straightened and cut wires in desired wire thicknesses to each other. According to the customer s request, transformer power and quantity, automatic length wire mechanism, twisting press and stacking robot can be added to panel welding machines.

It is a machine for straightening and cutting galvanized raw wires that is used in panel welding machines. Straightening and cutting machines consist of two parts, the main body and the wire opening drum. Straightening and cutting machines are designed for simple installation, ease of use, save time and reduce operating expenses. Wire straightening and cutting machine has 5 rolls. Straightens and cuts wire from a minimum of 50 cm to a maximum of 300 cm.

Profile flange welding robot is designed for welding square material to profile and pipe. Profile flange welding robot is designed to saving labor, high Daily capacity, easy to use and reduce operating costs. Profile flange welding robot can be controlled from the 4 touch screen with PLC automation system. Profile flange welding robot works with two 250 ampere welding machines.

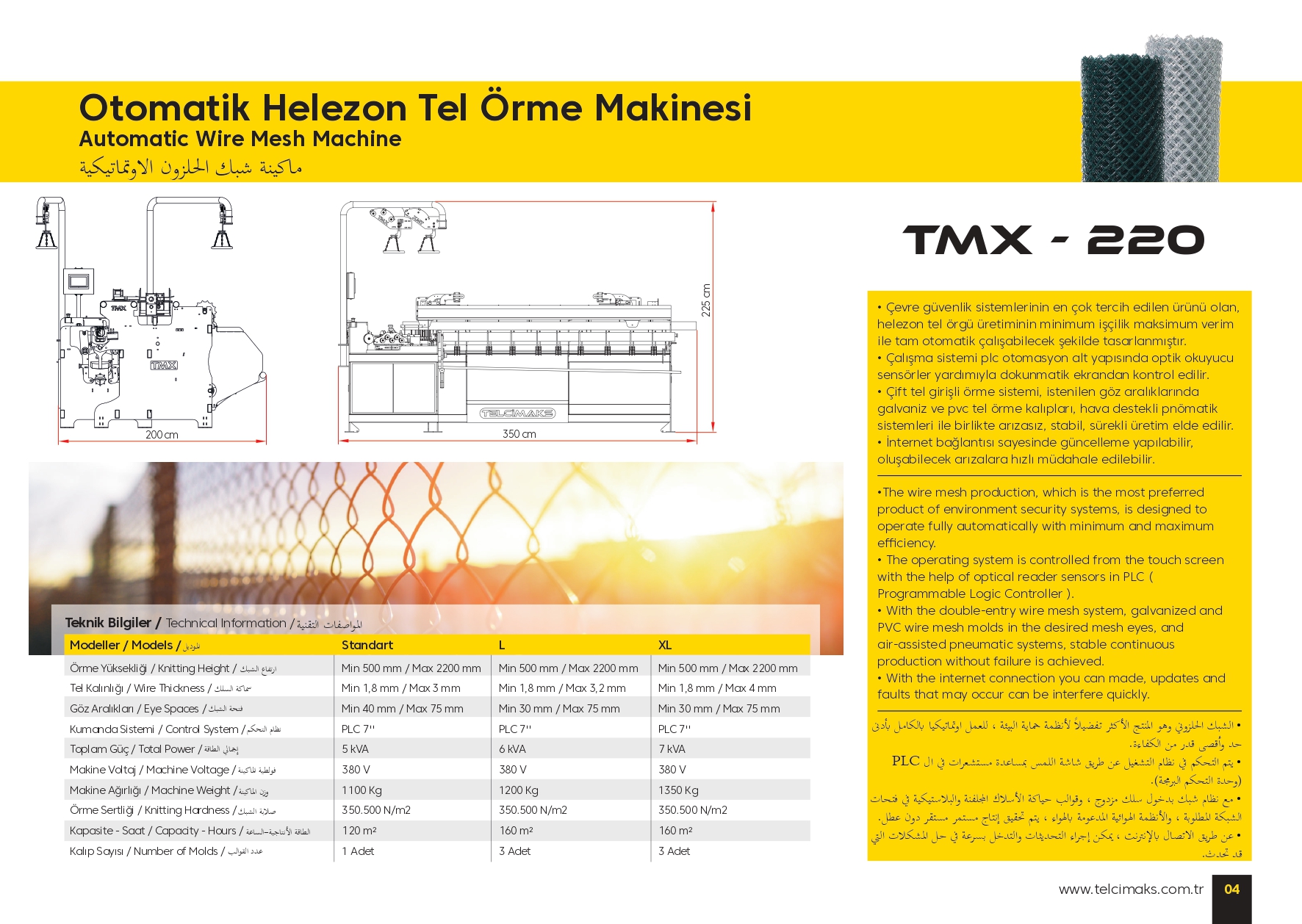

The wire mesh production, which is the most preferred product of environment security systems, is designed to operate fully automatically with minimum and maximum efficiency. The operating system is controlled from the touch screen with the help of optical reader sensors in PLC ( Programmable Logic Controller ). With the double-entry wire mesh system, galvanized and PVC wire mesh molds in the desired mesh eyes, and air-assisted pneumatic systems, stable continuous production without failure is achieved. With the internet connection you can made, updates and faults that may occur can be interfere quickly.

Helical wire mesh production, which is the most preferred product of perimeter security systems, is designed to work fully automatically with minimum labor and maximum efficiency. It is a machine designed to deliver the spiral wire mesh with less cost. It allows the wire mesh to take up less space, up to 500% compared to international container shipments.

Manual wıre bendıng press ıs a specially designed machine for bending panel fence wıres. It has 40 ton bending capacity. Twists are made for strong fence wires and resistance against external factors. Manual wire bending press works with pedal system. Form mold is shaped according to customer s request.

The machine can produce barbed wire which is extensively used in national defenses, military, railway, agriculture, animal husbandry and other industries. There are 2 main body wires and 2 barbed wire entrances. There are protective covers for security purposes. High capacity, easy to install and use.

It is galvanized on black raw wire prepared to be used in panel mesh welding machines. Electro galvanized coating ensures that the black raw wire is galvanized with chemical alloys and gains hardness. Electro galvanized coating consists of 10different boiler. If the customer want, a straightening and cutting machine can be added at the end of this line.

The wire mesh production, which is the most preferred product of environment security systems, is designed to operate fully automatically with minimum and maximum efficiency. The operating system is controlled from the touch screen with the help of optical reader sensors in PLC ( Programmable Logic Controller ). With the double-entry wire mesh system, galvanized and PVC wire mesh molds in the desired mesh eyes, and air-assisted pneumatic systems, stable continuous production without failure is achieved. With the internet connection you can made, updates and faults that may occur can be interfere quickly.

No represented companies found.

- TELCİMAKS

- TELCİMAKS TMX

TR

TR